One part of estimating the costs involved for a custom tube bending or tube lasering project involves simulating the machining process to determine cost, timing and resources needed to correctly meet the specifications for the part. This involves reviewing the geometry for the part or parts in specialized software and assigning timing and steps required to complete the laser cutting and/or tube bending operations.

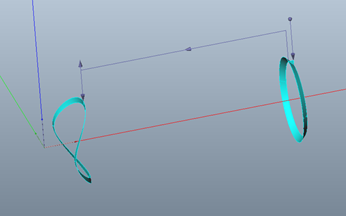

This process begins with the customer’s part drawing and/or CAD model. Files are uploaded to the software and reviewed in 3D. This digital view allows us to see all angles and dimensions of the part and the exact work that is needed. It also allows us to correctly program the machine to match the specific needs of the part.

In the software, you can also make notes about the project; helping to identify areas that may need extra attention or time, especially in the case of thicker material or unique requirements such as the use of micro joints, weld seam location, kerf and/or centering compensation. For custom tube bending and tube lasering, this is especially important, as it allows for a higher degree of accuracy and precision in the finished part, along with a more streamlined manufacturing process.

For example, in the screen shot below we can see that the part requires a bevel and a cope to fit onto its mate. The simulation tells us the amount of time this will take and how to best accommodate each part as well as each cut feature.

Whatever your tube bending or tube laser cutting needs, a simulation will most likely be required to accurately determine how your part will be manufactured. Normally the simulation must be done by a manufacturing engineer or someone in a similar technical role and is typically completed during the estimating process, since it provides details that may pertain to the costs or production time for the job. Once the project is green-lighted, the estimator or engineer can quickly refer to the simulation files and begin to program the operating system for the designated machine.

Simulation in custom tube bending or tube lasering is an important step to determine the best path to manufacturing. This step offers a detailed look into how the part needs to be processed so that the correct machines and procedures can be implemented to achieve the most accurate results for the customer.

This blog was authored by Marshall Arndt, manufacturing engineer, Sharpe Products.