Quality Assurance in Manufacturing

As a part of the manufacturing process, we do a thorough inspection of your part, so that we can verify the conformity to the part spec. Discover more in our blog, Dimensional Inspection in Tube Bending.

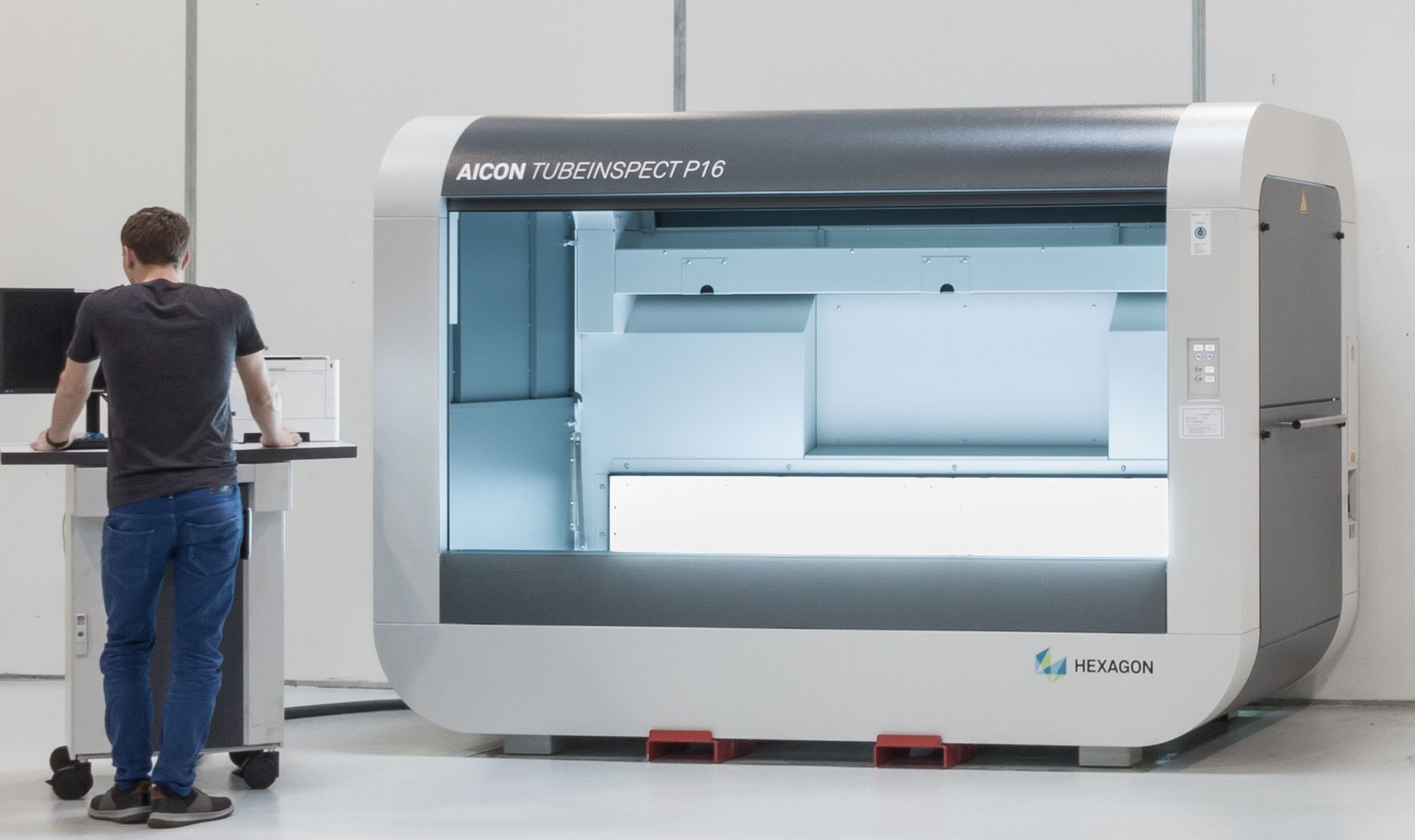

The TubeInspect P16 equipment we use in our facilities helps us verify accuracy during the tube bending process, offering real-time diagnostics and monitoring along with greater visibility to quality parameters from start to finish.

Using sixteen (16) digital, high-definition cameras, the equipment visually measures the dimensions and sizing of a bent tube, and verifies the angles and tolerances based on the specifications of the part. Any adjustments are then completed, resulting in shorter throughput to achieve a dimensionally accurate part.

Specifically designed for the needs of the industry, this equipment allows us to instantly measure tube bends and send corrections back to the tube-bending machines, resulting in reduced costs, set-up times and scrap. Find out more about this equipment here.

Advantages:

- Accurate and efficient set-ups

- Reduced inspection time

- Immediate results

Capabilities:

- Inspects parts in seconds with the click of a mouse

- Sends corrections back to the bender when needed

- Able to reverse engineer from existing parts or prototypes

CMM Inspection Arm & 3D Laser Scanner

For projects that require advanced, highly focused, inspection reporting we us a CMM inspection arm and 3D laser scanner. This gives us the ability to create a 3D model of the scanned part to compare to the original customer version, and make any adjustments needed to meet the spec.